Brand entsha yoqobo yesitokhwe soqobo se-IC Izixhobo zombane ze-Ic Chip Inkonzo ye-BOM DS90UB953TRHBRQ1

Iimpawu zeMveliso

| UHLOBO | INKCAZO |

| Udidi | IiSekethe eziDityanisiweyo (ICs) |

| Mfr | Texas Instruments |

| Uthotho | Iimoto, AEC-Q100 |

| Iphakheji | Iteyiphu & neReel (TR) Sika iTape (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Ubume beMveliso | Iyasebenza |

| Umsebenzi | Isiliyeli |

| Data Rate | 4.16Gbps |

| Uhlobo Longeniso | CSI-2, MIPI |

| Uhlobo Lwemveliso | FPD-Link III, LVDS |

| Inani lamagalelo | 1 |

| Inani leZiphumo | 1 |

| Voltage - Unikezelo | 1.71V ~ 1.89V |

| Ubushushu bokusebenza | -40°C ~ 105°C |

| Uhlobo lokuNqamisa | Intaba engaphezulu, iFlanki emanzi |

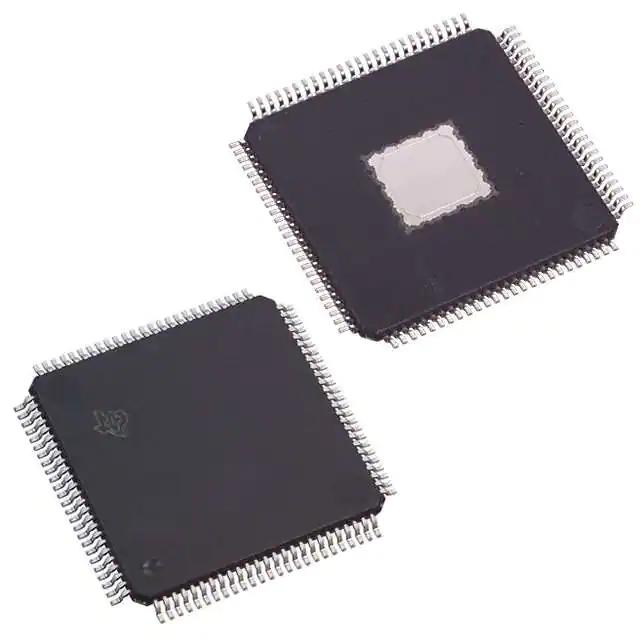

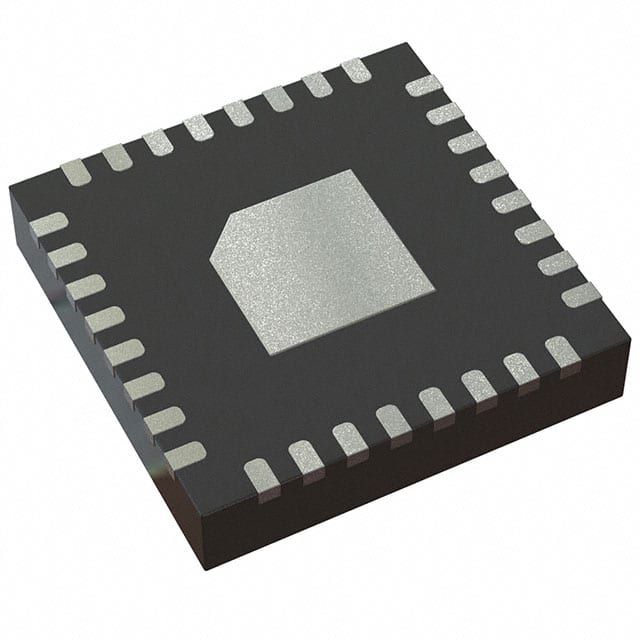

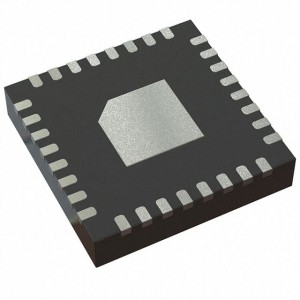

| Ipakethe / Ityala | I-32-VFQFN eveziweyo yePad |

| Supplier Device Package | 32-VQFN (5x5) |

| Inombolo yeMveliso esisiseko | I-DS90UB953 |

1.Kutheni i-silicon yeetshiphusi?Ngaba kukho izinto ezinokuthi endaweni yayo kwixesha elizayo?

Izinto ezikrwada zeetshiphusi zii-wafers, ezenziwe ngesilicon.Kukho ukungaqondi kakuhle ukuba "isanti ingasetyenziselwa ukwenza iitshiphusi", kodwa oku akunjalo.Eyona nxalenye yeekhemikhali zesanti yisilicon dioxide, kwaye eyona khemikhali iphambili yeglasi kunye neewafers nazo ziyisilicon dioxide.Umahluko, nangona kunjalo, kukuba iglasi i-polycrystalline silicon, kunye nokufudumeza isanti kumaqondo aphezulu okushisa kuvelisa i-polycrystalline silicon.Ii-wafers, kwelinye icala, ziyi-silicon ye-monocrystalline, kwaye ukuba zenziwe ngesanti kufuneka ziguqulwe ngakumbi ukusuka kwi-polycrystalline silicon ukuya kwi-silicon ye-monocrystalline.

Yintoni kanye kanye i-silicon kwaye kutheni ingasetyenziselwa ukwenza iichips, siya kutyhila oku kweli nqaku nganye nganye.

Into yokuqala ekufuneka siyiqonde kukuba imathiriyeli yesilicon ayikokutsiba ngokuthe ngqo kwinyathelo le-chip, isilicon icokiswa ukusuka kwisanti yequartz ngaphandle kwesilicon, inani leproton ye-silicon kune-aluminiyam enye ngaphezulu, kunento ye-phosphorus enye ngaphantsi. , ayisosiseko sezinto zekhompyutha zale mihla kuphela kodwa ikwangabantu abafuna ubomi bangaphandle komhlaba yenye yezinto ezisisiseko ezinokubakho.Ngokuqhelekileyo, xa i-silicon ihlanjululwa kwaye yacocwa (99.999%), inokuveliswa kwii-silicone wafers, ezithi ke zisikwe zibe ngamaqhekeza.Okukhona i-wafer ibhityile, kokukhona lisezantsi ixabiso lokwenziwa kwetshiphu, kodwa kokukhona ziphezulu iimfuno zenkqubo yetshiphu.

Amanyathelo amathathu abalulekileyo ekuguquleni i-silicon ibe ngamaqhekezana

Ngokukodwa, ukuguqulwa kwe-silicon kwii-wafers kunokwahlulwa kube ngamanyathelo amathathu: ukucocwa kwesilicon kunye nokucocwa, ukukhula kwe-silicon enye yekristale, kunye nokwenziwa kwe-wafer.

Ngokwendalo, i-silicon ifumaneka ngokubanzi ngohlobo lwe-silicate okanye i-silicon dioxide esantini nakwigrabile.Izinto eziluhlaza zifakwe kwisithando sombane se-arc kwi-2000 ° C kunye nobukho bomthombo wekhabhoni, kwaye ukushisa okuphezulu kusetyenziselwa ukusabela i-silicon dioxide ngekhabhoni (SiO2 + 2C = Si + 2CO) ukufumana i-silicon yebakala le-metallurgical (SiO2 + 2C = Si + 2CO) ubunyulu malunga ne-98%).Nangona kunjalo, oku kucoceka akwanelanga ukulungiselela amacandelo e-elektroniki, ngoko kufuneka kuhlanjululwe ngakumbi.I-silicon ye-metallurgical grade etyumkileyo ikloriniwe nge-gaseous hydrogen chloride ukuvelisa i-silane yolwelo, ethi emva koko i-distilled kwaye icuthwe ngokwekhemikhali ngenkqubo evelisa i-polysilicon ecocekileyo kunye nokucoceka kwe-99.9999999999% njenge-silicon yebakala lombane.

Ke uyifumana njani i-silicon ye-monocrystalline kwi-silicon ye-polycrystalline?Indlela eqhelekileyo yindlela yokutsala ngokuthe ngqo, apho i-polysilicon ifakwe kwi-quartz crucible kwaye ishushu ngobushushu be-1400 ° C ebanjwe kwi-periphery, eyenza i-polysilicon inyibilike.Ewe kunjalo, oku kwandulelwa ngokuntywila ikristale yembewu kuyo kwaye intonga yokuzoba ithwale ikristale yembewu kwelinye icala ngelixa icotha kwaye ithe nkqo iyitsalela phezulu isuka kwisilicon inyibilika.I-polycrystalline silicon inyibilika incamathela ezantsi kwekristale yembewu kwaye ikhule ibheka phezulu kwicala le-crystal lettice yembewu, ethi emva kokukhutshelwa ngaphandle kwaye ipholile ikhule ibe yikristale enye bar ene-lattice orientation efanayo njengekristale yembewu yangaphakathi.Okokugqibela, iiwafa ezinekristale enye ziyawa, zisikwe, zicolwe, zicocwe, kwaye zipolishwe ukuvelisa ezona ziqwenga zibalulekileyo.

Ngokuxhomekeke kubukhulu obusikiweyo, iiwafers zesilicon zingahlelwa njenge-6 ", 8", 12 ", kunye ne-18".Ubukhulu besayizi ye-wafer, iitshiphusi ezininzi zinokusikwa kwi-wafer nganye, kwaye iphantsi ixabiso le-chip nganye.

2.Amanyathelo amathathu abalulekileyo ekuguquleni i-silicon ibe ngamaqhekeza

Ngokukodwa, ukuguqulwa kwe-silicon kwii-wafers kunokwahlulwa kube ngamanyathelo amathathu: ukucocwa kwesilicon kunye nokucocwa, ukukhula kwe-silicon enye yekristale, kunye nokwenziwa kwe-wafer.

Ngokwendalo, i-silicon ifumaneka ngokubanzi ngohlobo lwe-silicate okanye i-silicon dioxide esantini nakwigrabile.Izinto eziluhlaza zifakwe kwisithando sombane se-arc kwi-2000 ° C kunye nobukho bomthombo wekhabhoni, kwaye ukushisa okuphezulu kusetyenziselwa ukusabela i-silicon dioxide ngekhabhoni (SiO2 + 2C = Si + 2CO) ukufumana i-silicon yebakala le-metallurgical (SiO2 + 2C = Si + 2CO) ubunyulu malunga ne-98%).Nangona kunjalo, oku kucoceka akwanelanga ukulungiselela amacandelo e-elektroniki, ngoko kufuneka kuhlanjululwe ngakumbi.I-silicon ye-metallurgical grade etyumkileyo ikloriniwe nge-gaseous hydrogen chloride ukuvelisa i-silane yolwelo, ethi emva koko i-distilled kwaye icuthwe ngokwekhemikhali ngenkqubo evelisa i-polysilicon ecocekileyo kunye nokucoceka kwe-99.9999999999% njenge-silicon yebakala lombane.

Ke uyifumana njani i-silicon ye-monocrystalline kwi-silicon ye-polycrystalline?Indlela eqhelekileyo yindlela yokutsala ngokuthe ngqo, apho i-polysilicon ifakwe kwi-quartz crucible kwaye ishushu ngobushushu be-1400 ° C ebanjwe kwi-periphery, eyenza i-polysilicon inyibilike.Ewe kunjalo, oku kwandulelwa ngokuntywila ikristale yembewu kuyo kwaye intonga yokuzoba ithwale ikristale yembewu kwelinye icala ngelixa icotha kwaye ithe nkqo iyitsalela phezulu isuka kwisilicon inyibilika.I-polycrystalline silicon inyibilika incamathela ezantsi kwekristale yembewu kwaye ikhule ibheka phezulu kwicala le-crystal lettice yembewu, ethi emva kokukhutshelwa ngaphandle kwaye ipholile ikhule ibe yikristale enye bar ene-lattice orientation efanayo njengekristale yembewu yangaphakathi.Okokugqibela, iiwafa ezinekristale enye ziyawa, zisikwe, zicolwe, zicocwe, kwaye zipolishwe ukuvelisa ezona ziqwenga zibalulekileyo.

Ngokuxhomekeke kubukhulu obusikiweyo, iiwafers zesilicon zingahlelwa njenge-6 ", 8", 12 ", kunye ne-18".Ubukhulu besayizi ye-wafer, iitshiphusi ezininzi zinokusikwa kwi-wafer nganye, kwaye iphantsi ixabiso le-chip nganye.

Kutheni le nto i-silicon iyeyona nto ifanelekileyo yokwenza iitshiphusi?

Ngokwethiyori, zonke ii-semiconductors zinokusetyenziswa njengezixhobo ze-chip, kodwa ezona zizathu ziphambili zokuba kutheni i-silicon iyona nto ifanelekileyo yokwenza iitshiphu zezi zilandelayo.

I-1, ngokomgangatho womxholo we-elementi yomhlaba, ngokulandelelana: ioksijini > i-silicon > i-aluminium > i-iron > i-calcium > i-sodium > i-potassium ...... inokubona ukuba i-silicon ibekwe kwindawo yesibini, umxholo mkhulu, ovumela kwakhona itshiphu ukuba ibe nonikezelo oluphantse lungapheli lwemathiriyeli ekrwada.

2, iipropathi zekhemikhali ze-silicon kunye neempawu zezinto eziphathekayo zizinzile kakhulu, i-transistor yokuqala kukusetyenziswa kwezixhobo ze-semiconductor i-germanium ukwenza, kodwa ngenxa yokuba iqondo lokushisa lidlula i-75 ℃, i-conductivity iya kuba lutshintsho olukhulu, lwenziwe kwi-PN junction emva kokubuyela umva. ukuvuza kwangoku kwegermanium kune-silicon, ngoko ke ukukhethwa kwe-silicon element njengesixhobo se-chip kufanelekile ngakumbi;

I-3, itekhnoloji yokucoca i-silicon ikhulile, kwaye inexabiso eliphantsi, ngoku ukucocwa kwesilicon kunokufikelela kwi-99.9999999999%.

I-4, imathiriyeli yesilicon ngokwayo ayinayo ityhefu kwaye ayinabungozi, ekwasesinye sezizathu ezibalulekileyo zokuba ikhethwe njengemathiriyeli yokuvelisa iitshiphusi.

.png)