Semiconductors Electronic Components TPS7A5201QRGRRQ1 Ic Chips BOM inkonzo Indawo enye yokuthenga

Iimpawu zeMveliso

| UHLOBO | INKCAZO |

| Udidi | IiSekethe eziDityanisiweyo (ICs) |

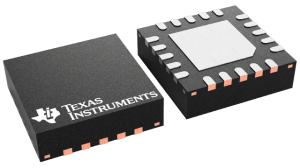

| Mfr | Texas Instruments |

| Uthotho | Iimoto, AEC-Q100 |

| Iphakheji | Iteyiphu & neReel (TR) Sika iTape (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Ubume beMveliso | Iyasebenza |

| Uqwalaselo Lwemveliso | Okuhle |

| Uhlobo Lwemveliso | Iyahlengahlengiswa |

| Inani labaLawuli | 1 |

| I-Voltage-Input (Ubukhulu) | 6.5V |

| Voltage-Imveliso (Min/Fixed) | 0.8V |

| Voltage-Imveliso (Ubukhulu) | 5.2V |

| Ukuyeka umbane (Ubukhulu) | 0.3V @ 2A |

| Okwangoku -Isiphumo | 2A |

| PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Iimpawu zokulawula | Vulela |

| Iimpawu zoKhuselo | Ngaphezulu kweqondo lobushushu, iReverse Polarity |

| Ubushushu bokusebenza | -40°C ~ 150°C (TJ) |

| Uhlobo lokuNqamisa | INtaba engaphezulu |

| Ipakethe / Ityala | 20-VFQFN Exposed Pad |

| Supplier Device Package | 20-VQFN (3.5x3.5) |

| Inombolo yeMveliso esisiseko | TPS7A5201 |

Isishwankathelo seechips

(i) Yintoni itshiphu

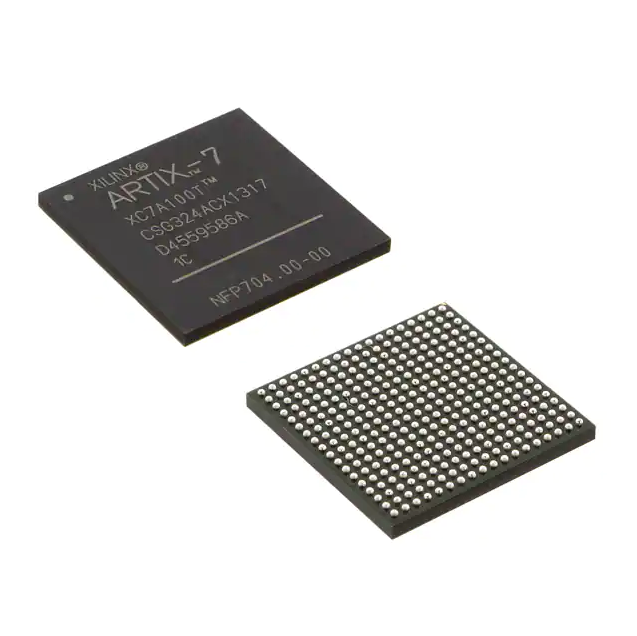

Isekethe edibeneyo, efinyeziweyo njenge-IC;okanye i-microcircuit, i-microchip, i-chip yindlela yokwenza iisekethe ezincinci (ingakumbi izixhobo ze-semiconductor, kodwa kunye namacandelo angenayo, njl.) kwizinto zombane, kwaye zihlala ziveliswa kumphezulu we-semiconductor wafers.

(ii) Inkqubo yokwenziwa kwetshiphu

Inkqubo epheleleyo yokwenziwa kwetshiphu ibandakanya uyilo lwetshiphu, ukwenziwa kwe-wafer, ukwenziwa kwephakheji, kunye novavanyo, apho inkqubo yokwenziwa kwe-wafer intsonkothile ngakumbi.

Okokuqala kuyilo lwetshiphu, ngokweemfuno zoyilo, "ipateni" eyenziweyo, into ekrwada yetshiphu sisisi esisicaba.

I-wafer yenziwe nge-silicon, ehluzwa kwisanti ye-quartz.I-wafer yinto ye-silicon ehlanjululweyo (99.999%), emva koko i-silicon ecocekileyo yenziwa kwiintonga ze-silicon, eziye zibe yimathiriyeli yokuvelisa i-quartz semiconductors yeesekethe ezidibeneyo, ezisikwe kwii-wafers zokuvelisa i-chip.Okukhona i-wafer ibhityile, kokukhona isezantsi ixabiso lemveliso, kodwa kokukhona inkqubo ifuna ngamandla.

Ukwaleka ngewafer

I-Wafer i-coating iyamelana ne-oxidation kunye nokumelana nobushushu kwaye luhlobo lwe-photoresist.

Uphuhliso lwe-Wafer photolithography kunye nokufaka

Ukuhamba okusisiseko kwenkqubo ye-photolithography kuboniswe kumzobo ongezantsi.Okokuqala, i-photoresist isetyenziswe kumphezulu we-wafer (okanye i-substrate) kwaye yomiswe.Emva kokumisa, i-wafer idluliselwa kumatshini we-lithography.Ukukhanya kugqithiswa kwimaski ukuze kuveliswe ipateni kwimaski kwifotoresist kumphezulu we-wafer, okwenza kube sesichengeni kunye nokuvuselela ukusabela kweefotochemical.Iiwafers eziveziweyo zibhakwa okwesibini, ezaziwa ngokuba yi-post-exposure baking, apho i-photochemical reaction iphelele ngakumbi.Okokugqibela, umphuhlisi utshizwa kwifotoresist kumphezulu wewafer ukuphuhlisa ipateni eveziweyo.Emva kophuhliso, ipateni kwimaski ishiywe kwi-photoresist.

I-Gluing, ukubhaka, kunye nokuphuhlisa zonke zenziwe kumphuhlisi we-screed kwaye ukuvezwa kwenziwa kwi-photolithograph.Umphuhlisi we-screed kunye nomatshini we-lithography zisebenza ngokubanzi kumgca, kunye nama-wafers ahanjiswa phakathi kweeyunithi kunye nomatshini usebenzisa i-robot.I-exposure yonke kunye nenkqubo yophuhliso ivaliwe kwaye i-wafers ayibonakali ngokuthe ngqo kwindawo engqongileyo ukunciphisa impembelelo yamacandelo ayingozi kwindalo kwi-photoresist kunye neempendulo ze-photochemical.

Doping ngokungcola

Ukufakela ii-ion kwi-wafer ukuvelisa i-P kunye ne-N-type semiconductors ehambelanayo.

Uvavanyo lwe-wafer

Emva kwezi nkqubo zingentla, i-lattice yedayisi yenziwa kwi-wafer.Iimpawu zombane zombane ngamnye zitshekishwa kusetyenziswa uvavanyo lwepin.

Ukupakishwa

Iziqwenga eziveliswayo zilungisiwe, zibotshelelwe kwizikhonkwane, kwaye zenziwe kwiipakethe ezahlukeneyo ngokweemfuno, yingakho i-chip core efanayo inokupakishwa ngeendlela ezahlukeneyo.Umzekelo, i-DIP, i-QFP, i-PLCC, i-QFN, njalo njalo.Apha imiselwa ikakhulu yimikhwa yesicelo somsebenzisi, indawo yesicelo, ifomathi yemarike, kunye nezinye izinto ezijikelezayo.

Uvavanyo, ukupakishwa

Emva kwenkqubo engentla, ukuveliswa kwe-chip kugqityiwe.Eli nyathelo kukuvavanya i-chip, ukususa iimveliso ezineziphene kwaye uzipakishe.

Ubudlelwane phakathi kweewafers kunye neechips

Itshiphu yenziwe ngaphezulu kwesixhobo esinye sesemiconductor.I-semiconductors ngokuqhelekileyo ziyi-diodes, i-triodes, iityhubhu zempembelelo yentsimi, i-resistors encinci yamandla, i-inductors, i-capacitors, njalo njalo.

Kukusetyenziswa kweendlela zobugcisa ukuguqula uxinaniso lwee-electron zasimahla kwinucleus yeathom kwiqula elilisetyhula ukuguqula izinto ezibonakalayo kwinucleus yeathom ukuvelisa intlawulo elungileyo okanye engalunganga yabaninzi (i-electron) okanye ezimbalwa (imingxuma) ukuya. yenza iisemiconductors ezahlukeneyo.

I-Silicon kunye ne-germanium zisetyenziswa ngokuqhelekileyo izixhobo ze-semiconductor kunye neempawu zabo kunye nezixhobo zifumaneka ngokulula ngobuninzi kwaye ngexabiso eliphantsi lokusetyenziswa kobu buchwepheshe.

I-silicon wafer yenziwe linani elikhulu lezixhobo ze-semiconductor.Umsebenzi we-semiconductor kukuba, kunjalo, ukwenza isekethe njengoko kufuneka kwaye ibekho kwi-silicon wafer.