Amacandelo oMbane IC Iitshiphu eziDityanisiweyo zeeSekethe IC TPS74701QDRCRQ1 indawo enye yokuthenga

Iimpawu zeMveliso

| UHLOBO | INKCAZO |

| Udidi | IiSekethe eziDityanisiweyo (ICs) |

| Mfr | Texas Instruments |

| Uthotho | Iimoto, AEC-Q100 |

| Iphakheji | Iteyiphu & neReel (TR) Sika iTape (CT) Digi-Reel® |

| Ubume beMveliso | Iyasebenza |

| Uqwalaselo Lwemveliso | Okuhle |

| Uhlobo Lwemveliso | Iyahlengahlengiswa |

| Inani labaLawuli | 1 |

| I-Voltage-Input (Ubukhulu) | 5.5V |

| Voltage-Imveliso (Min/Fixed) | 0.8V |

| Voltage-Imveliso (Ubukhulu) | 3.6V |

| Ukuyeka umbane (Ubukhulu) | 1.39V @ 500mA |

| Okwangoku -Isiphumo | 500mA |

| PSRR | 60dB ~ 30dB (1kHz ~ 300kHz) |

| Iimpawu zokulawula | Yenza, Amandla Alungileyo, Isiqalo esithambileyo |

| Iimpawu zoKhuselo | Ngoku, ngaphezulu koBubushushu, iSekethe eFutshane, phantsi kweVoltage Lockout (UVLO) |

| Ubushushu bokusebenza | -40°C ~ 125°C |

| Uhlobo lokuNqamisa | INtaba engaphezulu |

| Ipakethe / Ityala | I-10-VFDFN eveziweyo yePad |

| Supplier Device Package | I-10-VSON (3x3) |

| Inombolo yeMveliso esisiseko | TPS74701 |

Ubudlelwane phakathi kweewafers kunye neechips

Isishwankathelo seewafers

Ukuqonda ubudlelwane phakathi kwee-wafers kunye neechips, oku kulandelayo kukujongwa ngokubanzi kwezinto eziphambili ze-wafer kunye nolwazi lwe-chip.

(i) Yintoni isipha?

Ii-wafers zi-wafers ze-silicon ezisetyenziselwa ukuveliswa kweesekethe ezidibeneyo ze-silicon semiconductor, ezibizwa ngokuba zi-wafers ngenxa yobume bazo obusetyhula;ziyakwazi ukucutshungulwa kwii-silicone wafers ukuba zenze iindidi zamacandelo esekethe kwaye zibe yimveliso yesekethe edibeneyo kunye nemisebenzi ethile yombane.Isixhobo ekrwada se-wafers yisilicon, kwaye kukho i-silicon dioxide engaphelelwayo kumphezulu womhlaba.I-silicon dioxide ore ihlanjululwe kwii-arc zombane zombane, i-chlorinated nge-hydrochloric acid kunye ne-distilled ukuvelisa i-polysilicon ephezulu ecocekileyo kunye nococeko lwe-99.99999999999%.

(ii) Imathiriyeli esisiseko yeewafers

I-silicon isulungekiswa ukusuka kwisanti yequartz kwaye ii-wafers ziyacocwa (99.999%) ukusuka kwintonga ye-silicon, ethi emva koko yenziwe ibe ziintonga zesilicon ezithi zibe zizinto zequartz semiconductors kwiisekethe ezidibeneyo.

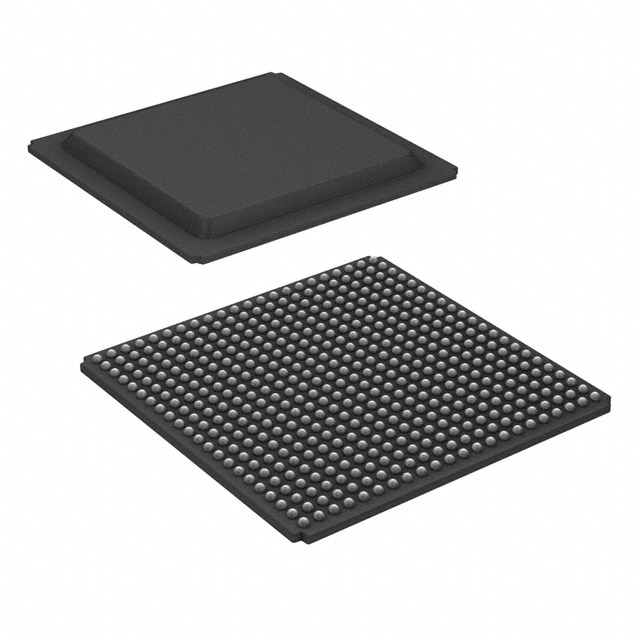

(iii) Inkqubo yokwenziwa kwewafer

Ii-wafers zizinto ezisisiseko zokwenza iitshiphusi zesemiconductor.Eyona nto ibalulekileyo yemathiriyeli ekrwada yeesekethe ezidityanisiweyo ze-semiconductor yisilicon kwaye ke ihambelana ne-silicon wafers.

I-silicon ifumaneka ngokubanzi kwindalo ngendlela ye-silicates okanye i-silicon dioxide ematyeni kunye neegrabile.Ukwenziwa kweewafers zesilicon kunokushwankathelwa ngamanyathelo amathathu asisiseko: ukucocwa kwesilicon kunye nokucocwa, ukukhula kwesilicon enye yecrystal, kunye nokwenziwa kwewafer.

Eyokuqala kukuhlanjululwa kwe-silicon, apho izinto eziluhlaza zesanti kunye negrabile zifakwa kwisithando sombane se-arc kwiqondo lokushisa elimalunga ne-2000 ° C kunye nobukho bomthombo wekhabhoni.Kubushushu obuphezulu, ikhabhoni kunye nesilicon diokside esantini nakwigrabile zifumana ikhemikhali (ikhabhoni idityaniswa neoksijini, ishiya isilicon) ukuze kufumaneke isilicon esulungekileyo enobunyulu obumalunga ne-98%, ekwabizwa ngokuba yi-silicon yebakala le-metallurgical, engeyiyo. ecocekileyo ngokwaneleyo kwizixhobo ze-microelectronic kuba iimpawu zombane ze-semiconductor izinto zinovakalelo kakhulu ekugxininiseni ukungcola.I-silicon yenqanaba le-Metallurgical ke ngoko ihlanjululwa ngakumbi: i-silicon yebakala le-metallurgical etyunyuziweyo iphantsi kwe-chlorination reaction kunye ne-gaseous hydrogen chloride ukuvelisa i-silane engamanzi, ethi ke idilizwe kwaye icuthwe ngokwekhemikhali ngenkqubo evelisa i-silicon ecocekileyo ye-polycrystalline ngobunyulu be-99.9999999999999999999999999999999 %, eba yisilicon yebakala lombane.

Okulandelayo kuza ukukhula kwesilicon ye-monocrystalline, eyona ndlela iqhelekileyo ebizwa ngokuba yi-direct pulling (indlela ye-CZ).Njengoko kubonisiwe kumzobo ongezantsi, i-polysilicon ecocekileyo ephezulu ifakwe kwi-quartz crucible kwaye ifudunyezwe ngokuqhubekayo kunye ne-graphite heater ejikeleze ngaphandle, igcina ubushushu malunga ne-1400 ° C.Igesi kwisithando somlilo ngokuqhelekileyo i-inert, ivumela i-polysilicon ukuba inyibilike ngaphandle kokudala ukuphendulwa kweekhemikhali okungafunwayo.Ukwenza i-crystals enye, i-orientation ye-crystals ilawulwa kwakhona: i-crucible ijikelezwe nge-polysilicon inyibilika, i-crystal yembewu igxininiswe kuyo, kwaye intonga yokudweba iqhutyelwa kwelinye icala ngelixa icotha kwaye ngokuthe nkqo iyitsalela phezulu ukusuka phezulu. I-silicon iyanyibilika.I-polysilicon enyibilikisiweyo inamathela ezantsi kwekristale yembewu kwaye ikhule ibheka phezulu kwicala le-lattice ilungiselelo lekristale yembewu.